Chitsulo chosapanga dzimbiri cha Duplex - Superduplex

Muzitsulo, chitsulo chosapanga dzimbiri ndi aloyi yachitsulo yokhala ndi chromium yosachepera 10.5% yokhala ndi zinthu zina zophatikizika kapena popanda zinthu zina komanso mpweya wopitilira 1.2%.Zitsulo zosapanga dzimbiri, zomwe zimadziwikanso kuti inox steels kapena inox kuchokera ku French inoxydable (inoxidizable), ndizitsulo zitsulozomwe zimadziwika bwino chifukwa cha kukana kwa dzimbiri, zomwe zimawonjezeka ndi kuchuluka kwa chromium.Kukana kwa dzimbiri kumathanso kukulitsidwa ndi nickel ndi molybdenum zowonjezera.Kukana kwazitsulo zazitsulo izi ku zotsatira za mankhwala a zowononga zimachokera ku passivation.Kuti passivation ichitike ndikukhalabe yokhazikika, aloyi ya Fe-Cr iyenera kukhala ndi chromium yocheperako pafupifupi 10.5% polemera, yomwe pamwamba pake imatha kuchitika ndipo pansipa sizingatheke.Chromium imatha kugwiritsidwa ntchito ngati chinthu chowumitsa ndipo imagwiritsidwa ntchito pafupipafupi ndi chinthu cholimba monga faifi tambala kuti apange makina apamwamba kwambiri.

Chitsulo chosapanga dzimbiri cha Duplex

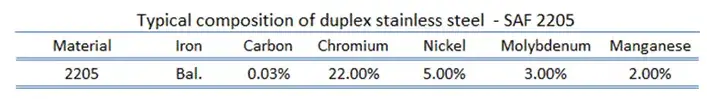

Monga dzina lawo likusonyezera, zitsulo zosapanga dzimbiri za Duplex ndizophatikiza mitundu iwiri ikuluikulu ya aloyi.Amakhala ndi ma microstructure osakanikirana a austenite ndi ferrite, cholinga chake nthawi zambiri chimakhala kupanga kusakaniza kwa 50/50, ngakhale, muzitsulo zamalonda, chiŵerengerocho chikhoza kukhala 40/60.Kukana kwawo kwa dzimbiri ndi kofanana ndi ma austenitic anzawo, koma kukana kwawo kupsinjika-kuwonongeka (makamaka kupsinjika kwa chloride kusweka kwa dzimbiri), kulimba kwamphamvu, komanso kutulutsa mphamvu (pafupifupi kuwirikiza kawiri mphamvu zokolola zazitsulo zosapanga dzimbiri za austenitic) nthawi zambiri zimakhala zapamwamba kuposa za austenitic. magiredi.Mu duplex zitsulo zosapanga dzimbiri, mpweya umasungidwa mpaka kutsika kwambiri (C<0.03%).Zomwe zili mu Chromium zimachokera ku 21.00 mpaka 26.00%, zomwe zili ndi nickel zimachokera ku 3.50 mpaka 8.00%, ndipo ma aloyiwa amatha kukhala ndi molybdenum (mpaka 4.50%).Kulimba ndi ductility nthawi zambiri zimagwera pakati pa ma austenitic ndi ma ferritic.Makalasi a Duplex nthawi zambiri amagawidwa m'magulu atatu kutengera kukana kwawo kwa dzimbiri: lean duplex, standard duplex, ndi superduplex.Zitsulo za Superduplex zalimbitsa mphamvu komanso kukana dzimbiri zamitundu yonse poyerekeza ndi zitsulo zokhazikika za austenitic.Zomwe zimagwiritsidwa ntchito nthawi zambiri zimaphatikizapo kugwiritsa ntchito m'madzi, zomera za petrochemical, zomera zowonongeka, zosinthanitsa kutentha, ndi makampani opanga mapepala.Masiku ano, makampani amafuta ndi gasi ndi omwe amagwiritsa ntchito kwambiri ndipo alimbikira kuti asamachite dzimbiri, zomwe zapangitsa kupanga zitsulo za superduplex.

Kukaniza kwachitsulo chosapanga dzimbiri ku zotsatira za mankhwala a corrosive agents kumachokera ku passivation.Kuti passivation ichitike ndikukhalabe yokhazikika, aloyi ya Fe-Cr iyenera kukhala ndi chromium yocheperako pafupifupi 10.5% polemera, yomwe pamwamba pake imatha kuchitika ndipo pansipa sizingatheke.Chromium imatha kugwiritsidwa ntchito ngati chinthu chowumitsa ndipo imagwiritsidwa ntchito pafupipafupi ndi chinthu cholimba monga faifi tambala kuti apange makina apamwamba kwambiri.

Duplex Stainless Steels SAF 2205 - 1.4462

Chitsulo chosapanga dzimbiri chodziwika bwino ndi SAF 2205 (chizindikiro cha Sandvik cha 22Cr duplex (ferritic-austenitic) chitsulo chosapanga dzimbiri), chomwe chimakhala ndi 22% chromium ndi 5% nickel.Ili ndi kukana kwambiri kwa dzimbiri komanso mphamvu zambiri, 2205 ndiye chitsulo chosapanga dzimbiri chomwe chimagwiritsidwa ntchito kwambiri.Mapulogalamu a SAF 2205 ali m'mafakitale otsatirawa:

- Transport, kusungirako, ndi kukonza mankhwala

- Zida zopangira

- Kuchuluka kwa kloridi ndi malo am'madzi

- Kufufuza mafuta ndi gasi

- Makina a pepala

Katundu wa Duplex Stainless Steel

Zinthu zakuthupi ndi katundu wambiri, zomwe zikutanthauza kuti sizidziimira pa kuchuluka kwa misa ndipo zimatha kusiyana ndi malo mkati mwa dongosolo nthawi iliyonse.Sayansi yazinthu imaphatikizapo kuphunzira kapangidwe kazinthu ndikuzigwirizanitsa ndi katundu wawo (makina, magetsi, ndi zina).Asayansi akadziwa za kulumikizana kwazinthu izi, amatha kupitiliza kuphunzira momwe zinthu zimagwirira ntchito pakugwiritsa ntchito.Zomwe zimatsimikizira kapangidwe kazinthu komanso momwe zimakhalira ndizomwe zimapangidwira komanso momwe zimapangidwira kukhala mawonekedwe ake omaliza.

Katundu Wamakina a Duplex Stainless Steel

Zipangizo zimasankhidwa kaŵirikaŵiri kuti zizigwiritsidwa ntchito mosiyanasiyana chifukwa zimakhala ndi mipangidwe yofunikira yamakina.Pazinthu zamapangidwe, zinthu zakuthupi ndizofunikira ndipo mainjiniya ayenera kuziganizira.

Mphamvu ya Duplex Stainless Steel

Mu mechanics of materials, themphamvu ya chinthundi kuthekera kwake kupirira katundu wogwiritsidwa ntchito popanda kulephera kapena kupunduka kwa pulasitiki.Kulimba kwa zida kumaganizira za ubale pakati pa katundu wakunja womwe umagwiritsidwa ntchito pazinthu zomwe zimapangidwira kapena kusintha kwazinthu.Mphamvu ya chinthu ndikutha kupirira katundu wogwiritsidwa ntchito popanda kulephera kapena kupunduka kwa pulasitiki.

Ultimate Tensile Mphamvu

Mphamvu yayikulu kwambiri ya duplex chitsulo chosapanga dzimbiri - SAF 2205 ndi 620 MPa.

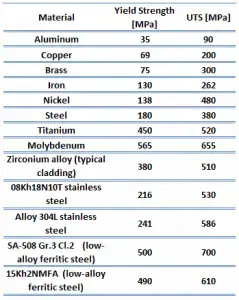

Themphamvu yomaliza yolimbandiye pazipita pa engineeringstress-strain curve.Izi zikufanana ndi kupsinjika kwakukulu komwe kumapangidwa ndi kamangidwe kazovuta.Mphamvu zokhazikika zokhazikika nthawi zambiri zimafupikitsidwa kukhala "mphamvu yolimba" kapena "chomaliza."Ngati kupsinjika uku kukugwiritsidwa ntchito ndikusungidwa, kusweka kumachitika.Nthawi zambiri, mtengowu ndi wochuluka kwambiri kuposa kupsinjika kwa zokolola (mochuluka 50 mpaka 60 peresenti kuposa zokolola zamitundu ina yazitsulo).Chinthu cha ductile chikafika ku mphamvu zake zomaliza, chimakumana ndi khosi pomwe gawo lopatsirana limachepetsa komweko.Mphepete mwa kupsinjika-kupsinjika mulibe kupsinjika kwakukulu kuposa mphamvu yomaliza.Ngakhale mapindikidwe amatha kupitilira kukula, kupsinjika nthawi zambiri kumachepa mukapeza mphamvu zomaliza.Ndi katundu wamba;choncho, mtengo wake sudalira kukula kwa chitsanzo choyesera.Komabe, zimatengera zinthu zina, monga kukonzekera kwa chitsanzo, kukhalapo kapena zolakwika zina zapamtunda, komanso kutentha kwa malo oyesera ndi zinthu.Mphamvu zolimba kwambiri zimasiyanasiyana kuchokera ku 50 MPa ya aluminiyamu mpaka 3000 MPa yachitsulo champhamvu kwambiri.

Themphamvu yomaliza yolimbandiye pazipita pa engineeringstress-strain curve.Izi zikufanana ndi kupsinjika kwakukulu komwe kumapangidwa ndi kamangidwe kazovuta.Mphamvu zokhazikika zokhazikika nthawi zambiri zimafupikitsidwa kukhala "mphamvu yolimba" kapena "chomaliza."Ngati kupsinjika uku kukugwiritsidwa ntchito ndikusungidwa, kusweka kumachitika.Nthawi zambiri, mtengowu ndi wochuluka kwambiri kuposa kupsinjika kwa zokolola (mochuluka 50 mpaka 60 peresenti kuposa zokolola zamitundu ina yazitsulo).Chinthu cha ductile chikafika ku mphamvu zake zomaliza, chimakumana ndi khosi pomwe gawo lopatsirana limachepetsa komweko.Mphepete mwa kupsinjika-kupsinjika mulibe kupsinjika kwakukulu kuposa mphamvu yomaliza.Ngakhale mapindikidwe amatha kupitilira kukula, kupsinjika nthawi zambiri kumachepa mukapeza mphamvu zomaliza.Ndi katundu wamba;choncho, mtengo wake sudalira kukula kwa chitsanzo choyesera.Komabe, zimatengera zinthu zina, monga kukonzekera kwa chitsanzo, kukhalapo kapena zolakwika zina zapamtunda, komanso kutentha kwa malo oyesera ndi zinthu.Mphamvu zolimba kwambiri zimasiyanasiyana kuchokera ku 50 MPa ya aluminiyamu mpaka 3000 MPa yachitsulo champhamvu kwambiri.

Zokolola Mphamvu

Mphamvu zokolola za duplex zitsulo zosapanga dzimbiri - SAF 2205 ndi 440 MPa.

Thezokolola mfundondi mfundo pa astress-strain curvezomwe zikuwonetsa malire a khalidwe lotanuka ndi chiyambi cha khalidwe la pulasitiki.Mphamvu zokolola kapena kupsinjika kwa zokolola ndizinthu zomwe zimatanthauzidwa ngati kupsinjika komwe zinthu zimayamba kupunduka pulasitiki.Mosiyana ndi izi, zokololazo ndi pamene kusintha kosasinthika (elastic + pulasitiki) kumayambira.Pamaso pa zokolola, zinthuzo zidzawonongeka elastically ndikubwerera ku mawonekedwe ake oyambirira pamene kupsinjika komwe kumagwiritsidwa ntchito kumachotsedwa.Pamene zokolola zadutsa, gawo lina la deformation lidzakhala lokhazikika komanso losasinthika.Zitsulo zina ndi zinthu zina zimasonyeza khalidwe lotchedwa zotulukapo phenomenon.Mphamvu zokolola zimasiyana kuchokera ku 35 MPa ya aluminiyamu yamphamvu kwambiri mpaka 1400 MPa yachitsulo champhamvu kwambiri.

Young's Modulus of Elasticity

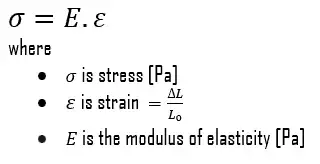

Young's modulus of elasticity of duplex stainless steel - SAF 2205 ndi 200 GPa.

Young modulus ya elasticityndi elasticity modulus ya kupsinjika ndi kupsinjika kwa mzere wokhazikika wa uniaxial deformation ndipo nthawi zambiri imawunikiridwa ndi mayeso olimba.Kufikira kuchepetsa kupsinjika, thupi lidzatha kubwezeretsanso miyeso yake pakuchotsa katundu.Kupanikizika komwe kumagwiritsidwa ntchito kumapangitsa kuti maatomu omwe ali mu kristalo asunthike kuchoka pamalo awo olingana, ndi zina zonsema atomuamasamutsidwa mulingo womwewo ndikusunga geometry yawo.Zopanikizika zikachotsedwa, maatomu onse amabwerera pamalo awo oyambirira, ndipo palibe kusintha kosatha komwe kumachitika.Malinga ndiLamulo la Hooke, kupsinjika kumayenderana ndi kupsyinjika (m'dera lotanuka), ndipo otsetsereka ndi modulus ya Young.Young's modulus ndi ofanana ndi kupsinjika kwa nthawi yayitali komwe kugawidwa ndi kupsyinjika.

Kuuma kwa Duplex Stainless Steel

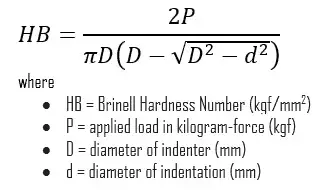

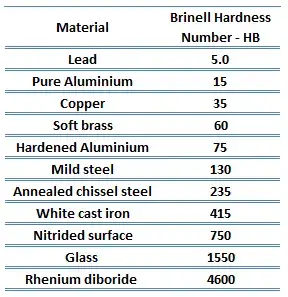

Brinell kuuma kwa duplex zitsulo zosapanga dzimbiri - SAF 2205 ndi pafupifupi 217 MPa.

Mu sayansi ya zinthu,kuumandikutha kupirira kulowera pansi (kupindika kwa pulasitiki) ndikukanda.Kuuma ndi chinthu chomwe sichidziwika bwino kwambiri chifukwa chimatha kuwonetsa kukana kukanda, kukwapula, kulowa mkati, ngakhale kukana kupangidwa kapena kupindika kwa pulasitiki.Kuuma ndikofunikira pamalingaliro aukadaulo chifukwa kulimba kwamadzi kumawonjezeka ndi kulimba kapena kukokoloka ndi nthunzi, mafuta, ndi madzi.

Mu sayansi ya zinthu,kuumandikutha kupirira kulowera pansi (kupindika kwa pulasitiki) ndikukanda.Kuuma ndi chinthu chomwe sichidziwika bwino kwambiri chifukwa chimatha kuwonetsa kukana kukanda, kukwapula, kulowa mkati, ngakhale kukana kupangidwa kapena kupindika kwa pulasitiki.Kuuma ndikofunikira pamalingaliro aukadaulo chifukwa kulimba kwamadzi kumawonjezeka ndi kulimba kapena kukokoloka ndi nthunzi, mafuta, ndi madzi.

Brinell kuuma mayesondi amodzi mwa mayeso olimba a indentation opangidwa kuti ayese kuuma.Mu mayeso a Brinell, cholembera cholimba, chozungulira chimakakamizika pansi pa katundu wina wake pamwamba pa chitsulo kuti chiyesedwe.Mayeso anthawi zonse amagwiritsa ntchito mpira wachitsulo wolimba wa 10 mm (0.39 mu) ngati cholowera chokhala ndi mphamvu ya 3,000 kgf (29.42 kN; 6,614 lbf).Katunduyo amasungidwa mosalekeza kwa nthawi yodziwika (pakati pa 10 ndi 30 s).Kwa zipangizo zofewa, mphamvu yaying'ono imagwiritsidwa ntchito;Pazinthu zolimba, mpira wa tungsten carbide umalowetsedwa m'malo mwa mpira wachitsulo.

Mayesowa amapereka zotsatira za manambala kuti ayese kuuma kwa zinthu, zomwe zimawonetsedwa ndi nambala ya Brinell hardness - HB.Nambala ya kuuma kwa Brinell imasankhidwa ndi miyezo yoyesera yomwe imagwiritsidwa ntchito kwambiri (ASTM E10-14[2] ndi ISO 6506–1:2005) monga HBW (H kuchokera kuuma, B kuchokera ku Brinell, ndi W kuchokera ku inndenter, tungsten (wolfram) carbide).M'miyezo yakale, HB kapena HBS ankagwiritsidwa ntchito kutanthauza miyeso yopangidwa ndi zolembera zachitsulo.

Nambala yolimba ya Brinell (HB) ndi katundu wogawidwa ndi malo a indentation.Kutalika kwa chithunzicho kumayesedwa ndi maikulosikopu yokhala ndi sikelo yowoneka bwino.Nambala yolimba ya Brinell imawerengedwa kuchokera ku equation:

Pali njira zingapo zoyesera zomwe zimagwiritsidwa ntchito nthawi zonse (mwachitsanzo, Brinell,Knoop,Vickers,ndiRockwell).Pali matebulo omwe akupezeka ogwirizanitsa manambala a kuuma kuchokera ku njira zosiyanasiyana zoyesera zomwe zimagwirizanitsa.M'mamba onse, nambala yolimba kwambiri imayimira chitsulo cholimba.

Katundu Wotentha wa Duplex Stainless Steel

Thermal katundu wa zipangizo amanena kuyankha kwa zipangizo kusintha awokutenthandi kugwiritsa ntchitokutentha.Monga cholimba chimatengamphamvumu mawonekedwe a kutentha, kutentha kwake kumakwera, ndipo miyeso yake imawonjezeka.Koma zida zosiyanasiyana zimatengera kugwiritsa ntchito kutentha mosiyanasiyana.

Kuchuluka kwa kutentha,kukulitsa kutentha,ndimatenthedwe madutsidweNthawi zambiri zimakhala zofunikira kwambiri pakugwiritsa ntchito zolimba.

Malo Osungunuka a Duplex Stainless Steel

Malo osungunuka a duplex zitsulo zosapanga dzimbiri - SAF 2205 zitsulo ndi kuzungulira 1450 ° C.

Kawirikawiri, kusungunuka ndi kusintha kwa gawo la chinthu kuchoka ku cholimba kupita kumadzimadzi.Themalo osungunukacha chinthu ndi kutentha kumene gawoli limasintha.Malo osungunuka amatanthauziranso momwe zolimba ndi zamadzimadzi zimatha kukhalapo mofanana.

Thermal Conductivity ya Duplex Stainless Steel

Kutentha kwazitsulo za duplex zosapanga dzimbiri - SAF 2205 ndi 19 W / (m. K).

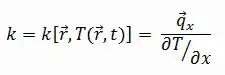

Makhalidwe otengera kutentha kwa zinthu zolimba amayezedwa ndi katundu wotchedwa thematenthedwe madutsidwe, k (kapena λ), yoyezedwa ndi W/mK Imayesa mphamvu ya chinthu kutumiza kutentha kudzera mu chinthuconduction.Zindikirani kutiLamulo la Fourierimakhudza zinthu zonse, posatengera momwe zilili (zolimba, zamadzimadzi, kapena gasi).Choncho, amatanthauzidwanso zamadzimadzi ndi mpweya.

Thematenthedwe madutsidwezamadzimadzi zambiri ndi zolimba zimasiyana malinga ndi kutentha, komanso pa nthunzi, zimatengeranso kuthamanga.Mwambiri:

Zida zambiri zimakhala zofanana, choncho nthawi zambiri timatha kulemba k = k (T).Matanthauzo ofananawo amalumikizidwa ndi ma conductivity amafuta mumayendedwe a y- ndi z (ky, kz), koma pazinthu za isotropic, kutulutsa kwamafuta sikudalira kuwongolera, kx = ky = kz = k.

Nthawi yotumiza: Feb-04-2023